| Our

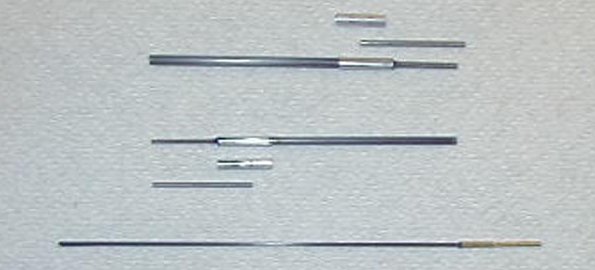

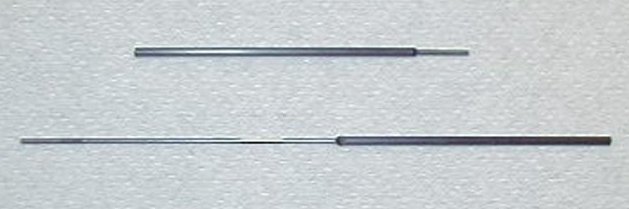

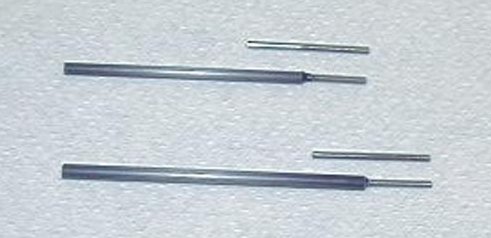

PushRods are carbon fiber tubes. We stock three diameters and they

are the best PushRods we have ever found for RC applications. They

are lighter than the 1/4" square balsa we used to use

Each size has a use in different applications. They all work great.

They are used for racers as well as the Giant Scale airplanes. The

hole in the center of the 1/8" PushRod is a slip fit for a 2-56

Dubro threaded rod (not All-thread) and the 5/32" PushRod is a slip

fit for a 4-40 Dubro threaded rod (not All-thread). The 3/16" will

accept 4-40 all-thread. The threads are an excellent gluing surface.

In the instructions, we will show you several ways to connect different

fittings.

Before you install any metal fitting in any PushRod, clean the metal

fitting with a solvent like lacquer thinner or whatever you have

in the shop. Then sand the metal fitting with a rough grit sand

paper to scratch it for good glue adhesion. We have found that medium

cure epoxy, slow cure Ca, JB Weld all work very well. We have just

tested the new Rubberized Ca IC-2000™ available from

Bob Smith and the product that NHP sells under the name of Black

Flash. It is fast and extremely strong. Plus it does not get brittle

and should never break from a shock.

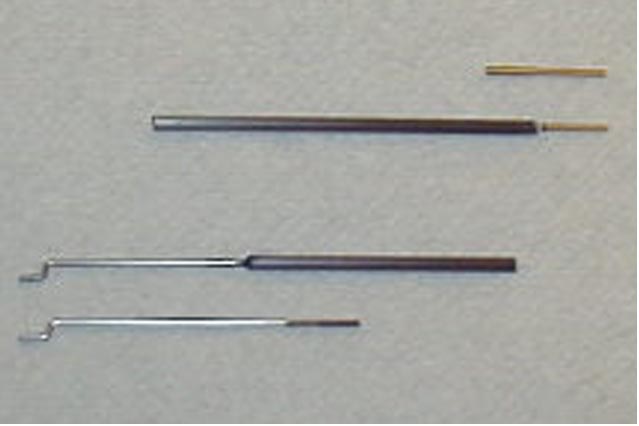

We also have a product that is perfect for flying wires. It is .060

x 36" solid carbon rod. A 1/16" Dubro threaded coupler and our recommended

glues make a perfect attachment. They are small, light, and extremely

strong in tensile strength. They will not stretch! When you use

the Dubro threaded couplers, thoroughly CLEAN the INSIDE of the

hole before you glue the rod in. Some of them still have machine

oil in them and no glue will bond to the oil surface.

|